Gantry Beam for Hire Best at hire

• Gantry girders would have to be doubly symmetric, or have the top flange fully restrained. What are the options? Looking back at the BS 5950 examples in the SCI library, most are mono-symmetric with a channel welded to the top flange. An example with a plain plate welded to the top flange is presented in early editions of the 'Red Book'2.

Gantry Girder What, Why and How YouTube

In this paper, a 2x400 ton gantry crane main beam is designed. Analytical stress calculations and analysis with numerical method are made. Afterwards the results of analytical calculations.

中国の橋形クレーンメーカー|Dafang Crane

Thus, an improved rotatable gantry design was needed to control, shape and scan broad-energetic beams for efficient transport and tumour conformal dose delivery. In this paper, we present a new gantry design via improving the previous design (see Masood et al ) by a two step beam capturing system and simplified energy selection system, ISESS.

Design of Gantry Girders (Part no 1) Steel Structure IS 8002007 By

Crane gantry girder design (EN1993) This video demonstrates the Tekla Tedds Crane gantry girder design calculation. The calculation checks the design of simply supported gantry girders comprising of either a plain I section, an I section with a capping plate or an I section with a capping channel, carrying a conventional overhead or an.

What is a Gantry Crane? A Closer Look at the Different Types and Design

Gantry Beam. A gantry beam, also known as a gantry crane or gantry framework, is a structural component used to support and guide the movement of a gantry system. It is typically a large horizontal beam that spans an open space and provides a platform for hoisting and moving heavy objects. Gantry Girder Design

AS Beam Gantry System

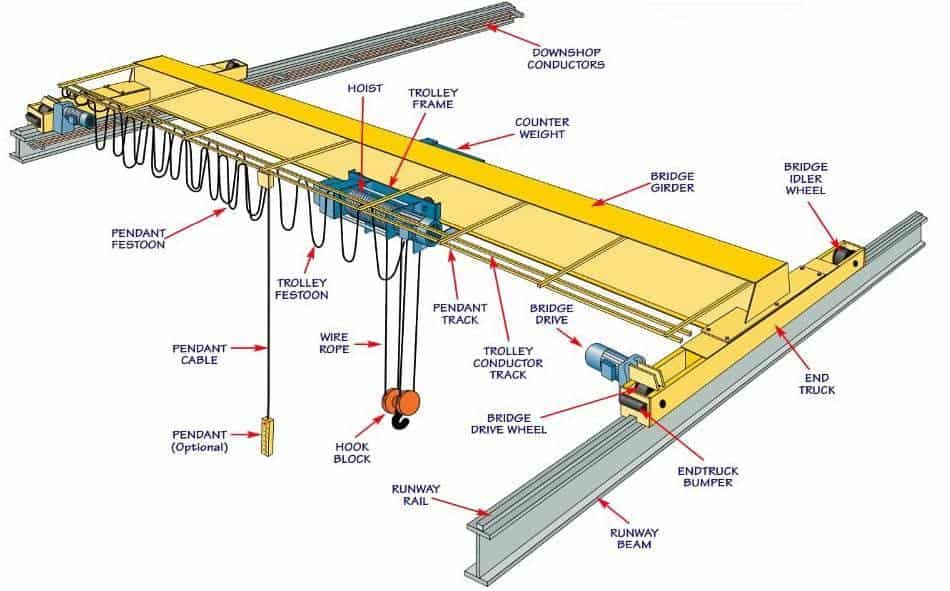

Design Procedure for Gantry Cranes 297 8 Crane Runway Beams 8.1 GENERAL Overhead travelling cranes or gantry cranes as shown in Figure 8.1 are generally used in workshops and warehouses where lifting capacity is required over a large proportion of the floor area.

Chapter 6. Gantry Girder Design of Steel Structures [Book]

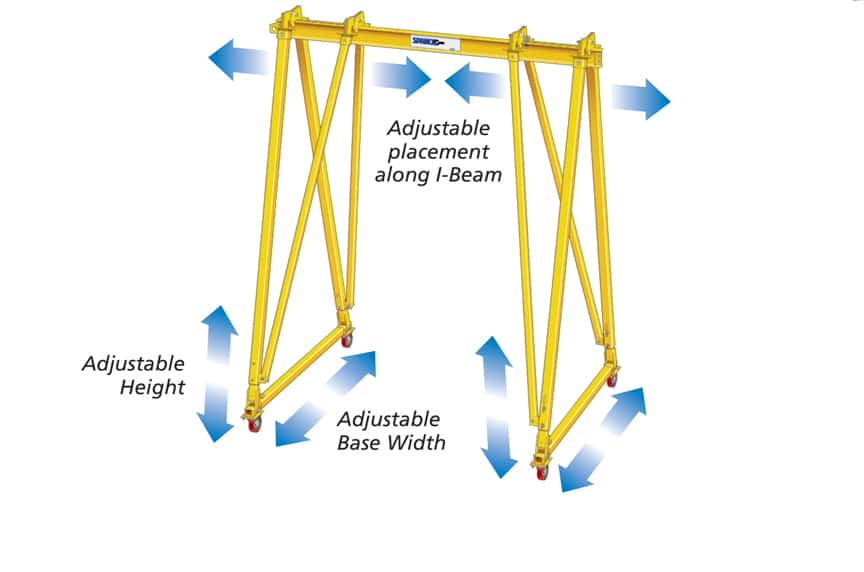

Upsized Gantry Crane Plans. Single top I-beam design — 8 ft to 30 ft width options. Telescoping of fixed legs — 7 ft to 16 ft height options. Options from 1000 lb. to 6000 lb. capacity. Note: Some length, height and capacity options are mutually exclusive. Options for Steel (stronger) or Aluminum (lighter, for mobility).

500kg Lightweight Aluminium Gantry c/w 4mtr Beam Safety Lifting

Gantry Standard Shape I-Beam Flange Width Chart Categories: How To and Helpful Information | Tags: Gantry Cranes I-Beams (named because of their shape) provide great load-bearing support. I-Beams or American Standard Shape I-Beams, like the one shown above, have tapered flanges for added strength.

Gantry Beam Design Bending Beam (Structure)

The following are the main design basis that engineers should consider when designing a gantry girder: 1. Loading Conditions: The first step in gantry girder design is to determine the maximum load that the structure will be required to support. This includes both the static load of the gantry and the dynamic load of the moving loads such as.

11kv 2 pole structure drawing highschoolcardboardsculpture

Self-Centering Beam Support. A Wallace gantry crane is the embodiment of design elegance. The self-centering beam support design provides several advantages over more rigid beam suspension methods in mobile cranes. Wallace Tri-Adjustable, Hippolift, and made-to-order 15-ton models all use this proprietary design.

2500kg Aluminium Gantry, 5mtr beam, 16002200mm Safety Lifting

The design of a gantry crane girder, therefore, involves the selection of a suitable and workable steel model and section to satisfy the machine (crane) requirements, loading, equipment, etc without leading to any structural or service failure. Normally, for medium-duty (say 25 to 30 t capacity) cranes, standard universal rolled I-beams are used.

Crane Runway Beam Design Excel The Best Picture Of Beam

1. Introduction. Typically, in proton therapy (PT) facilities, a gantry is the last section of the beamline for multiple-field irradiation. A gantry rotates around a straight line from the coupling point which joins the previous fixed beamline to the iso-center, then bends horizontal beam to the direction that is perpendicular to the irradiation plane.

2000kg Aluminium Gantry, 6mtr beam, 16002200mm Safety Lifting

The design loads on the gantry girder depends upon the minimum or the closest approach distance of the hook from the axis of the gantry girder. ADVERTISEMENTS: In the usual case, the gantry girder is laterally unsupported. Hence it is a practice to strengthen the top compression flange by making it wider using channels.

Gantry Beam Design The Best Picture Of Beam

A gantry crane is a type of overhead crane with a single or double girder configuration supported by freestanding legs that move on wheels or along a track or rail system. Gantry cranes are usually considered when there is a reason not to incorporate an overhead runway system.

Diy Gantry Crane Wood Homemade Gantry Crane Modifications

The design of the gantry girder is a specific example of a laterally unsupported beam. It is subjected to in extension to vertical loads and horizontal loads along and perpendicular to its axis. Loads are dynamic and generate vibration. The compression flange needs critical attention. Gantry Girder Design

What is a Gantry Crane? A Closer Look at the Different Types and Design

Gantry girders or crane girders convey hand-run or electrically run overhead cranes to industrial buildings such as factories, workshops, steelworks, etc. to raise huge materials, equipment, etc., and to carry them from one end to the other end, within the building.